I'm new to the saltwater reefing world but plan on jumping in feet first. So far I've been collecting everything I'll need to get set up.

I'm currently building a stand for my 125 gallon (72''/20''/19'') and utilizing a 55 gallon for my sump/fuge (48''/13''/20'').

Check it out!

I wanted to have full access to the front without support beams getting in the way. I ended up doing this by using two 2x6's as a cross beam to take the "brunt" of the weight. I've seen other stands with no support beams what-so-ever; so, I feel confident.

I used a pocket jig to "toenail" some of the screws in for added support

I saved some serious cash by grabbing old furniture parts from IKEA's "As Is" section. I picked up those black all wood cabinet doors for two bucks a piece, no joke!

What might be the biggest challenge is building the "shell" around the base. In order to have full access I want to be able to pull the whole face off.

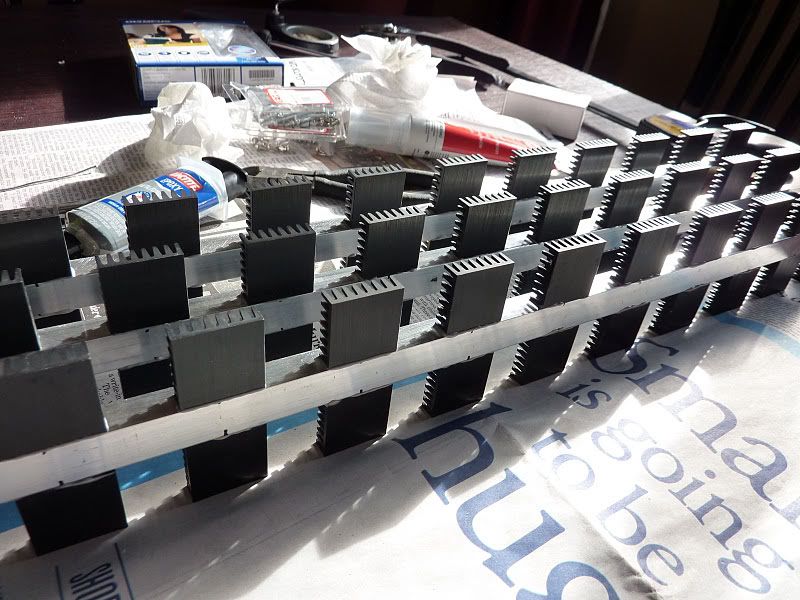

I used Liquid Nails and wooden dawdles throughout to better reinforce the stand.

When I bought most of the items I have it came with a lot of extras. I have a bunch of things I won't be using like a acrylic wet/dry sump and aquariums. Send me a message if you need anything, maybe we can just trade extras? Just ask, I might have it!

I also have a few sheets of 1/4'' 36x48 acrylic I plan on making a custom sump out of at a later date. I haven't decided on a design yet, but, a fuge is very important to me.

More to come...

Reply With Quote

Reply With Quote

Bookmarks