(PLEASE CLICK ON THE PICTURES TO SHOW THEM FULL WIDTH.....I don't know what size to change them to for the site)

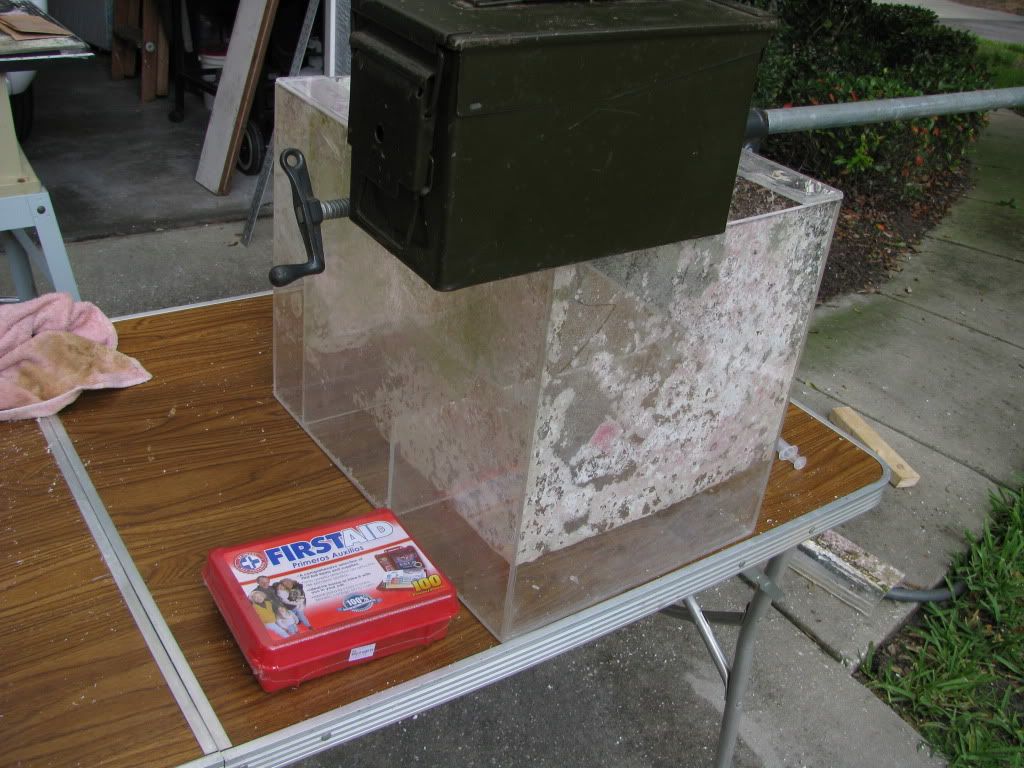

Josh came over and we did the deed....this is the fuge as we started on it....

this thing was serious tall for a fuge....it's laying on its side in this picture

Most people cut acrylic with either a router, jigsaw or table saw....I will show the use of a scroll saw, a table saw and a router....

First, I ran the Table Saw...I read once that if you run the blade all the way up and feed slowly that there is the least chance of cracking....

Please note: I do not endorse using a table saw without a blade guard and push sticks...I just happen to live dangerously and to do it like this...

This is the type of edge you get from a table saw....still requires a bit of sanding for a good gluing edge....

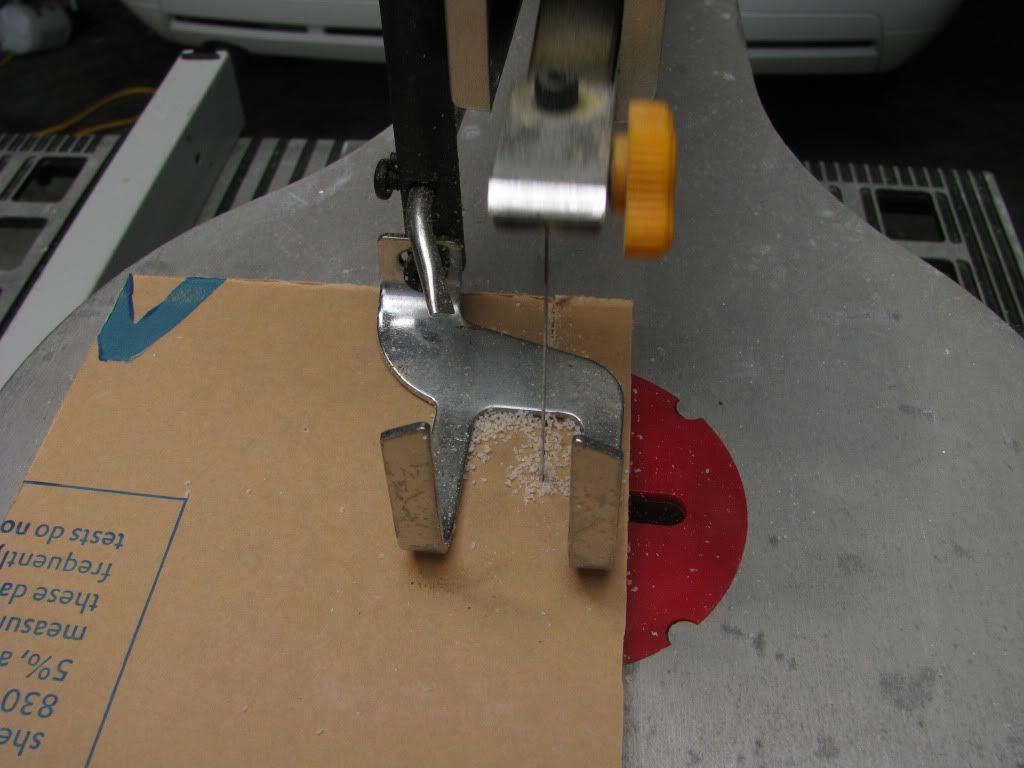

Next, I cut a piece using my Scroll saw....

Scroll saws and jigsaws allow some really neat curve cutting....

The edge from a scroll saw is much tidier than with a jigsaw, but these also require a bit of sanding before gluing...

The actual cutting of the fuge was done with a router and a straight cutoff bit....Here is the fuge being cut after jigging up the board as a guide....

nice war-face Josh....

This leaves the best edge by far, but unfortunately I didn't snap any....

So, we got it cut, and had to do a little bit of extra effort to cut the existing internal baffle, but we aren't illustrating that....after cutting a couple of strips from the side of the part we cut off, we glued them up to pull the old bowing in....

A bit of clamping and a weight to keep the corner down and it ended up good....

We let that set up and added a bead of honey thick Weld-on #16 to the joints of the bracing and Josh had to go, so there is no "After" picture....sorry... but it is now 16 inches tall versus the original 28 I think it was...and is a much more livable size....

Hope this helps somebody out at some point.....

Mitch

Reply With Quote

Reply With Quote

Bookmarks