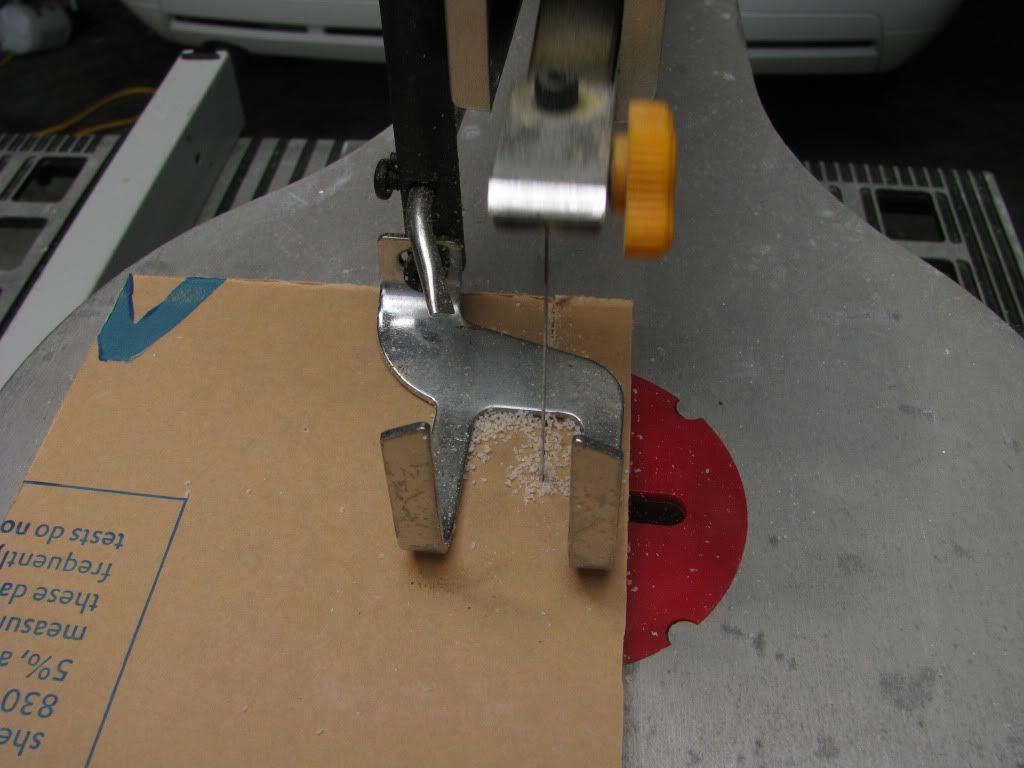

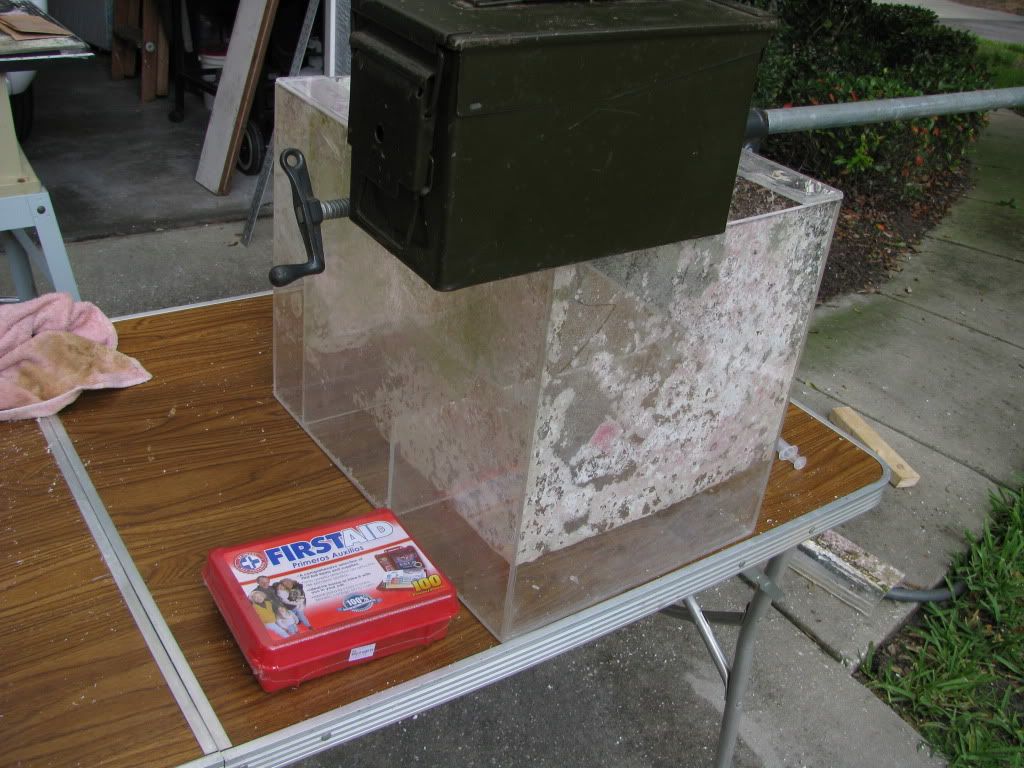

Josh (CheekyMonkey) called me and said his Fuge for the 120G is WAAAYYYYYYY too tall to work well, and asked what would be involved in shortening it up a bit....I said he could bring it over and we will cut it down some. He said it's thin Acrylic, so cracking will be an elevated risk....I have a couple of tricks up my sleeve and I think we will be okay...

I have some extra material, so I will figure I will pull out the camera and the different tools and show some hints and tips....

More to follow......

Reply With Quote

Reply With Quote

Bookmarks